The NAS 1523 Stat-O-Seal is designed with a pre-calculated interference factor built into the teardrop shaped elastomeric seal designed for applications requiring NAS 1523 conformance.

Stat-O-Seal NAS1523

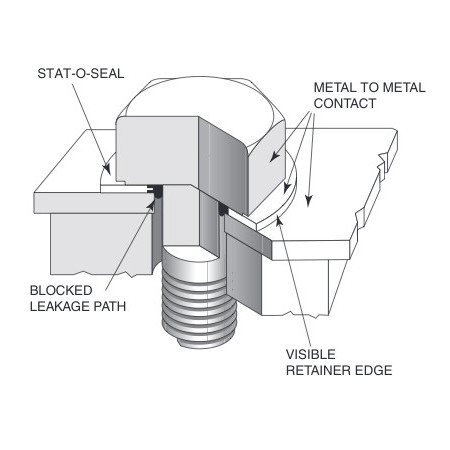

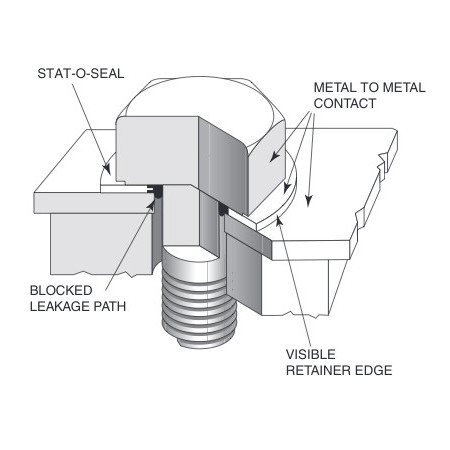

The NAS 1523 Stat-O-Seal is designed with a pre-calculated interference factor built into the teardrop shaped elastomeric seal designed for applications requiring NAS 1523 conformance. The cross-section free height of the rubber is greater than the metal retainer, providing the proper compression without squeezing the seal beyond its elastic limit.

NAS 1523 Stat-O-Seal Features:

NAS 1523 Stat-O-Seals offer users long and reliable service, a high degree of reusability and easy assembly.

The NAS 1523 Stat-O-Seal's unique features provide many advantages and benefits as shown below:

As the fastener is installed into the mating hardware, the NAS1523 Stat-O-Seal is compressed down to the retainer thickness. The retainer provides a positive alternate load path for fastener torque and forms a protective gland area for the confinement of the seal in a controlled state. Since the elastomer seal cannot move outward, the mass of the seal is forced inward against the shank of the fastener and against the mating surfaces, creating a positive seal. This principle is known as controlled confinement sealing. The diameter of the fastener head should always exceed that of the maximum "E diameter" in order to preserve this principle.

Specifications