McFarlane Aviation offers FAA/PMA approved throttle, propeller and mixture controls for many single engine Cessna, Piper, Grumman and Bellanca aircraft. Please view the Eligibility Chart or click "View Eligible Aircraft" above to determine the correct part number for your specific aircraft.

MC600 Series Universal Solid Wire Vernier Mixture Control

Precise mixture control for less money!

McFarlane Push-Pull Controls

McFarlane Aviation offers FAA/PMA approved throttle, propeller and mixture controls for many single engine Cessna, Piper, Grumman and Bellanca aircraft. Please view the Eligibility Chart or click "View Eligible Aircraft" above to determine the correct part number for your specific aircraft.

Custom engine controls can be manufactured for aircraft not listed in the approved application charts. All McFarlane custom control cables are built to customer provided specifications. McFarlane custom engine controls duplicate the original customer supplied controls in regards to length, thread size and pitch, wear sleeve locations, diameter and travel length. McFarlane custom controls are manufactured to the same standards using the same materials, rigorous testing and inspections as our FAA-PMA products. Custom controls are not FAA-PMA approved. For ordering details, go to the Custom Engine Control Page.

See the Customer Testimonials page for what others say about McFarlane controls.

Our engine and propeller controls incorporate a number of unique features that make McFarlane Controls the highest quality engine and propeller controls on the market:

Metal Construction

Unlike the controls of our competitors that use plastic, McFarlane control fittings and components are made from anodized aluminum, stainless steel, plated steel, and brass. All critical swage connections are metal for continued dependability. Our Vernier controls feature locking devices that are precision formed and heat treated in all critical wear areas.

A Superior Conduit System

McFarlane Aviation's unique conduit has always been the heart of our controls. The conduit is made from carbon steel wire that has been specially formed for increased strength and to give a smooth inside diameter. Two of these specially formed wires are coiled in tandem for increased tensile strength without sacrificing flexibility. A Teflon jacket extruded over the coiled housing provides additional strength and wear resistance to chafing. A virgin Teflon liner occupies the center of the conduit to reduce friction and ensure reliable operation at all temperature extremes. This system gives our controls good flexibility and smooth low friction operation even when routed with multiple tight bends. The tandem long lay coiling gives our controls good tensile strength and a solid feel under heavy push loads without sacrificing routing flexibility.

Knobs Make a Difference

Our "pilot friendly" knobs are all compression molded from a reinforced phenolic or a reinforced melamine-phenol resin. Unlike the soft injection molded knobs of our competitors, our knobs are hard and thermally stable. They resist scratching and do not deteriorate with age. The McFarlane knobs meet the latest F.A.R. requirements for shape and color.

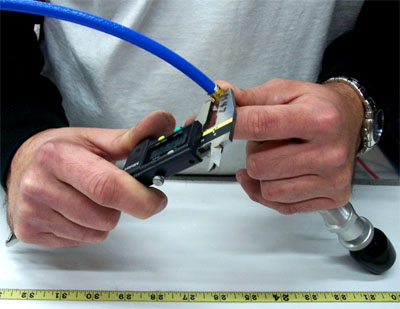

Vibration Dampening Features

The McFarlane metal swivel joints have a unique Viton rubber vibration dampening sleeve with a spring load system that dampens engine induced vibration in the push rod guide tube and metal swivel joint. Molded Viton boots are also used on the push rod guides to seal out contaminates. The Viton rubber withstands the high temperatures of the engine environment while resisting degradation from oil and solvents. This system drastically reduces the vibration fretting and wear that leads to premature control failure.

Special Lubrication

During assembly, the McFarlane controls have a special lifetime lubrication applied to critical sliding surfaces. This molybdenum disulfide and Teflon based lubricant with a synthetic grease base has been specially formulated to reduce friction and prevent galling and contamination locking of the control components from -70 deg F to over 1000 deg F. This lubricant is available only in McFarlane Aviation controls.

Consistent Quality

The assembly of McFarlane engine controls is interrupted many times for inspections of all critical elements to ensure only the highest quality controls are produced. Each inner wire swage, each push rod, each conduit fitting and terminal is inspected by our assembly team. As a further measure of quality, a second inspector also checks each critical detail to make sure only controls of the highest quality pass inspection. Attention is given to every detail at McFarlane Aviation. For instance, we verify the torque required to operate every vernier control to ensure it operates properly and has that smooth feel our customers have come to expect.

Tough in any Environment

McFarlane controls have had an outstanding performance and reliability record in all environments. Bush pilots like our controls because they work freely at 50 deg below zero and have been proven in harsh salt water environments. Temperatures approaching the melting point of the steel components cannot stop the McFarlane controls from functioning. We have tested our controls in the harshest environments to ensure that they will provide a long reliable service life for the most demanding engine installations.

Time Tested

With over 25 years of experience building aircraft engine controls and with thousands of units in airplanes flying on every continent (yes, even Antarctica), McFarlane controls have a proven track record and are universally recognized for their high quality.

Recommended Service Life

Due to the criticalness of engine controls and considering their operating environment, the maximum recommended in service time for McFarlane engine controls is equal to the maximum time between engine overhauls as recommended by the engine manufacturer. However, you may find that over time, the friction lock mechanism on your McFarlane throttle control does not seem to hold its position as well as it did in the past. We have a solution for that! To learn more, please read Extend the Life of Your McFarlane Throttle Control by Matt Sharpton, A&P Mechanic.

Alternate for :

| 45-024-2 | |

| 345-024-3 | |

| 9862010-1 | |

| 9862010-3 | |

| S1234-11 | |

| S1234-5 |